Common fault treatment of vibration motor

Date: Oct. 29, 2021

If you are interested in our products, Please get in contact with us .

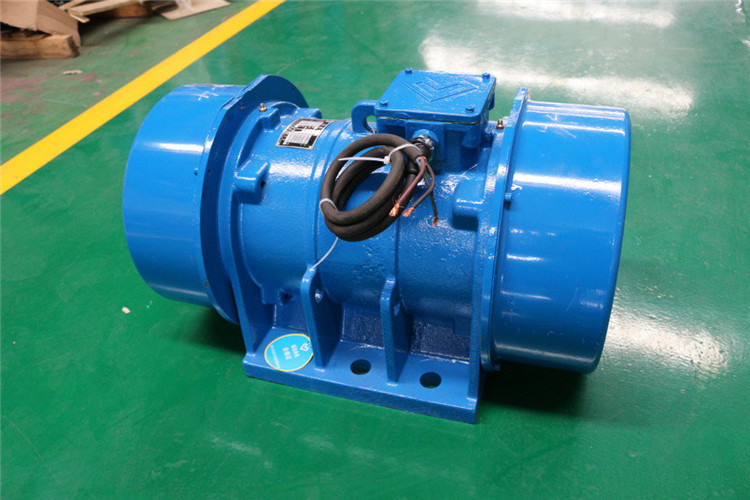

Date: Oct. 29, 2021 Chat Line Send InquiryVibration source The three-phase asynchronous motor integrates the power source and the vibration source. It is an energy-saving excitation source, small in size, large in excitation force, reliable in structure, easy to use and maintain, and is referred to as vibration motor. This series of products are widely used in various vibration equipment such as vibrating feeders, vibrating conveyors, vibrating sand shakers, vibrating crushers, and small and medium-sized vibrating screens. It is an ideal excitation source for mechanized screening, conveying, crushing, filling and anti-clogging of powder, granular, block and other bulk materials.

Common fault treatment of vibration motor

1. After the vibration motor is turned on, the motor does not start, so check:

1) Whether the power supply lacks phase;

2) Whether the motor is open phase;

3) Whether the protective cover is damaged and rubs the eccentric block;

2. After starting up, the motor is noisy, heats up, etc., should be checked:

1) Whether the roughness of the contact surface between the vibrating machine and the motor foot meets the installation requirements;

2) Whether the anchor bolts are tightened;

3) Whether the vibration acceleration of the vibration motor host meets the requirements for use;

3. After adjusting the eccentric block, the amplitude changes abnormally. You should check whether the eccentric block at both ends of the rotating shaft is adjusted symmetrically;

4. In the vibration equipment with two vibration motors working at the same time, when the phase rotation does not meet the requirements, the phase sequence of the single unit must be adjusted, and the phase sequence of the total power supply of the two vibration motors must not be adjusted.

LZZG vibration motor Features

1 Vibration acceleration does not exceed twice the acceleration of gravity.

2 The use environment temperature does not exceed 40℃ (if it exceeds, the power should be reduced appropriately).

3 The altitude of the use area does not exceed 1000m (when it exceeds 1000m, the temperature will be increased every 100m.

The rising limit should be lowered by 5℃, and the higher limit should not exceed 4000m for use).

4 The temperature rise of the winding of the motor shall not exceed 80k (measured by resistance transmission).

5 The higher temperature of the motor bearing is not allowed to exceed 90°C.

6 There should be no conductive dust in the operating environment, and no explosive, flammable or highly corrosive gas.

7 The vibration power of the main engine must not exceed the calibration parameters of the first equipped motor, otherwise, the excitation force should be reduced.

8 The vibration motors of this motor series are all three-phase power frequency 50Hz, 380V alternating current.

Previous:Hydrocyclone separator operation and attention problems

Next:Mine restoration treatment: green sand and gravel production plant

Send us a message

You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!